+86 183 6377 3366

+86 183 6377 3366 News Categories

Featured News

0102030405

Medium borosilicate medicinal glass bottles - the "safety guardian" of domestic high-end pharmaceutical packaging

2025-10-21

Amid the global upgrading wave of pharmaceutical packaging, borosilicate pharmaceutical glass bottles have become the core packaging choice for vaccines, biological agents, high-end injections and other pharmaceutical products due to their excellent chemical stability and compatibility. In recent years, Chinese enterprises have broken through technical bottlenecks, realizing large-scale Domestic production of borosilicate pharmaceutical glass bottles, ending the long-term international monopoly, and solidifying the safety of the pharmaceutical supply chain.

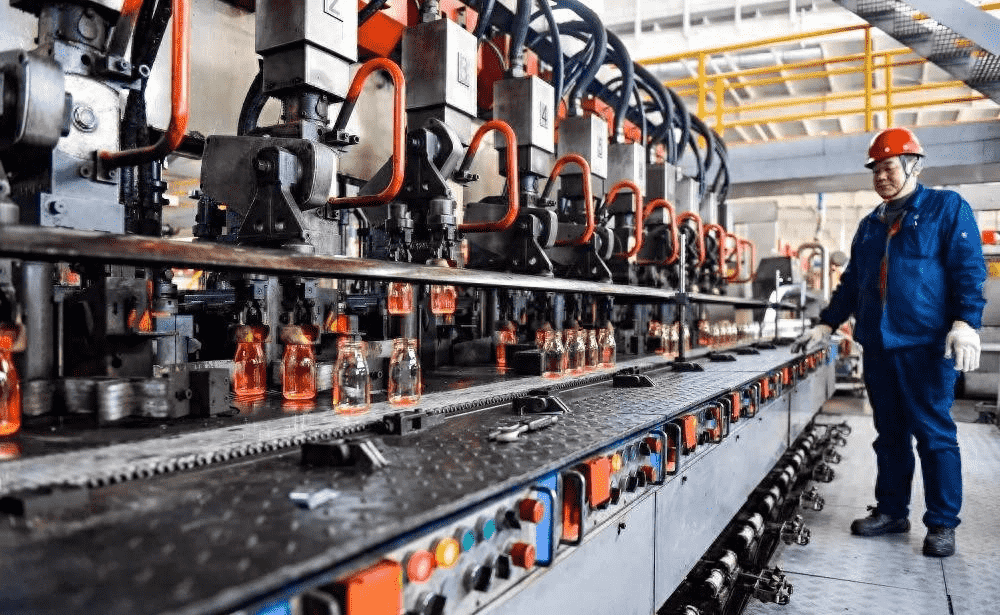

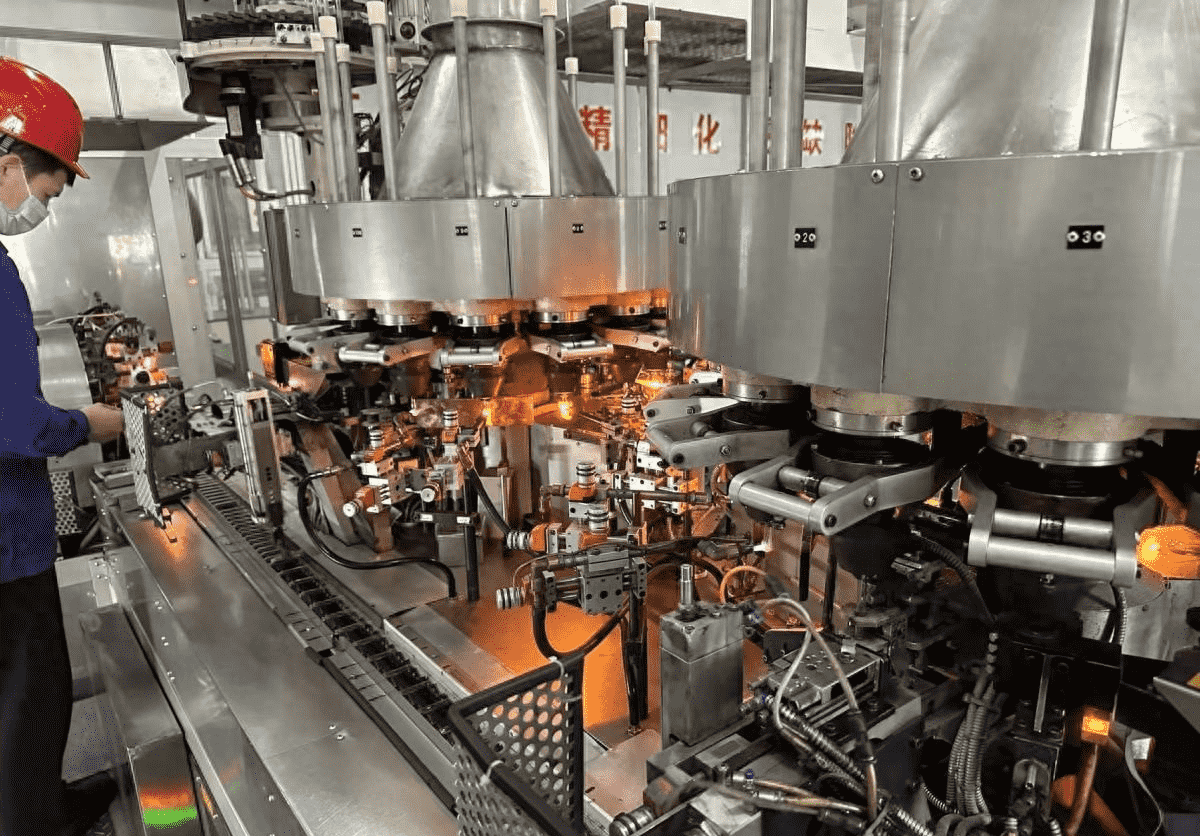

Leading enterprises such as Hebei Kaisheng Junheng and Cangzhou Four Star Glass have taken the lead in achieving technological breakthroughs. In their production workshops, robotic arms operate precisely, advancing the entire process from glass tube cutting, forming to inspection and packaging in a fully automated manner. Kaisheng Junheng's borosilicate pharmaceutical glass production line adopts advanced temperature control technology to ensure the uniformity of glass materials. The products can withstand high-temperature sterilization and long-term storage, meeting the strict requirements of biological agents; Four Star Glass's products have passed multiple global pharmaceutical packaging certifications, are exported to all over the world, and have become trusted partners of international pharmaceutical enterprises. Henan Ancai Hi-Tech has further built a dual production base layout, with an annual designed production capacity of 10,000 tons of colorless borosilicate pharmaceutical glass tubes. Its holding subsidiary Xinhe Industry can produce 5,000 tons of brown borosilicate glass tubes annually, supporting an annual production capacity of 600 million controlled injection bottles and 1 billion pharmaceutical ampoules. The products are exported to South Korea, India, Russia and other countries, forming a complete industrial chain from raw materials to finished products.

The rise of domestic borosilicate pharmaceutical glass bottles has not only reduced the import dependence of high-end pharmaceutical packaging by more than 40% but also achieved breakthroughs in key performances - the smoothness of the inner wall of the bottle has been improved by 30%, reducing drug adsorption loss; the water resistance meets the international first-class standard, avoiding the dissolution of glass components affecting drug efficacy. With the participation of new forces such as Hunan enterprises, the localization process of key materials such as 5.0 borosilicate glass tubes has accelerated, providing a solid guarantee for the high-quality development of the pharmaceutical industry.